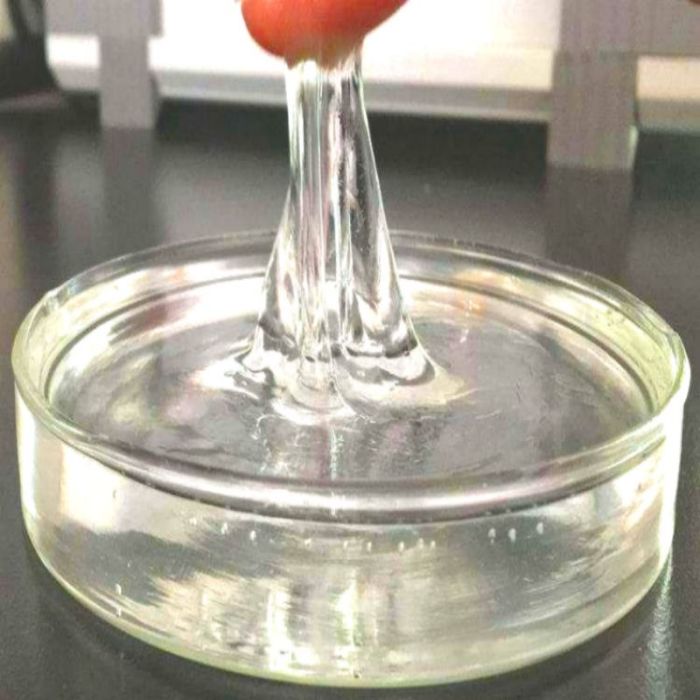

ZC6523 is a trifunctional polyurethane acrylate synthesized by polymerization of polyester polyol, aromatic isocyanate curing agent and hydroxyethyl acrylate, also known as photosensitive curing resin. Its technical index: viscosity is 5000-6000mpa S / 25 ℃, acid value < 0.5 (NCO%), functionality 3 (theoretical value), color number: 1# (Gardner); This product has the advantages of good flexibility, wear resistance, scratch resistance, heat resistance, water resistance, high reaction activity and so on. It is widely used in the fields of light curing ink, wood furniture, floor coating, paper coating, plastic coating, optical fiber coating, metal coating and adhesive.